- How to choose an ozone generator

- About ozone

- coronavirus

- Water ozonation

- Ozonation of fruit and vegetables

- Contact

- Vehicle ozonation

- Ozone concentration

- Ways of ozonation

- The use of ozone in industry

- Air Ozonizers

- Ozonation of cereals

- Ozone treatment in the meat industry

- Ozonation in cold rooms

- Fire - ozonation

- Ozone breakdown in water

- Allergy

- Ozone compatible materials

- Decontamination of air conditioning with ozone

- Ozone water treatment

- Home ozone generator

- Mushrooms

- Sewage ozonation

- Ozonation of hotel rooms

Prospects for the use of ozone in pest control of stored cereals

Professor dr hab. Stanisław Ignatowicz OZONE - treatment using a mixture of ozone and air to destroy pests Insect losses and problem Over 500 million dollars each year.There are fewer and fewer plant protection products for controlling pests in storage.

Insect resistance to the means used.

Ozone An alternative - ozone gas.

Ozone Over 100 scientific publications.

Some of them indicate that relatively low conc. ozone (50 ppm) is sufficient to destroy harmful organisms:insects,

mites,

molds,

bacteria,

other organisms.

Ozone - a highly sterilizing reactive gas - used for:

drinking water disinfection,disinfection of medical equipment,

destroying bacteria

lowering the level of mycotoxins,

food sanitization,

deodorization,

removal of discolorations,

It breaks down to atmospheric oxygen Produced on site.

It breaks down to atmospheric oxygen Produced on site. There is no need to store gas in cylinders.

It cannot be supplied e.g. in cylinders - it degrades to oxygen on its own.

There is no need for damage when it has not been used. Toxic to insects The mechanism of toxic effects on insects - damage to the respiratory system. Corn Roll

rice roll

biting triplet

the troika

granary borer,

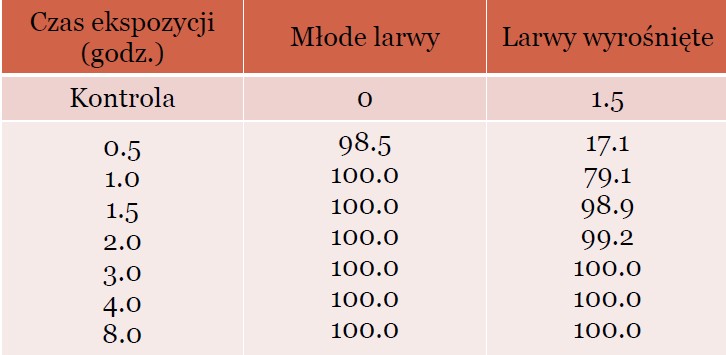

flour flour. Literature data on the effectiveness of ozone in pest control ozone used in conc.

from <45 ppm to 10,000 ppm for several hours - several days.

causes 100% mortality depending on the q target species and fumigation parameters:

temperature,

O2 / CO2 concentrations

pressure (vacuum),

other factors. No ozonation effect at 0.3 ppm for 22-26 days American visitor, Periplaneta americana

Nauphoela cinerea

fire ant, Solenopsis invicta

100% mortality 5 ppm for 3-5 days

100% mortality 5 ppm for 3-5 days the troika

granary

100% mortality 95-115 ppm for 3.5 - 6 hours

100% mortality 95-115 ppm for 3.5 - 6 hours the troika

biting triplet

100% mortality 50 ppm for 3 days

100% mortality 50 ppm for 3 days the troika

corn almond

> 90% mortality 25-50 ppm for 3-5 days

> 90% mortality 25-50 ppm for 3-5 days biting triplet

corn almond

LT95 95-120 ppm

LT95 95-120 ppm biting triplet (LT95 = 70 min);

rice roll (LT95 = 100 hours

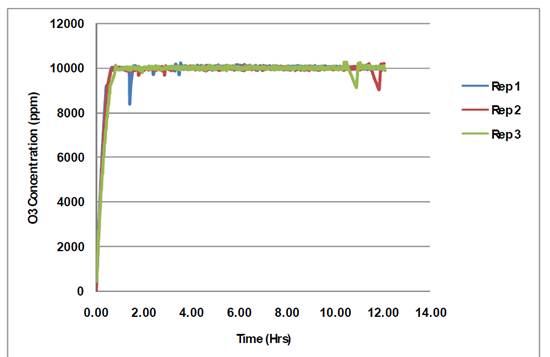

10,000 ppm

10,000 ppm Temp. 13oC, vacuum or reduced pressure -25.4 mm Hg for 6 hours

Hypothenemus hampei 100% mortality in all stages except eggs (approx. 15% survived).

Echidnas skin, Dermestes maculatus

Spiky skin of 10,000 ppm

Spiky skin of 10,000 ppm

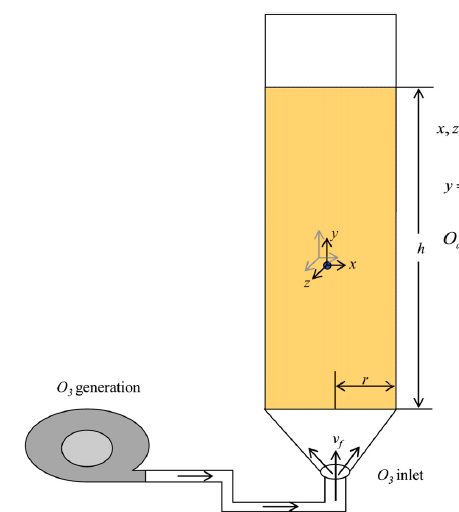

Ozone flow in silo grain mass possible in three directions: y, x, z

Ozone flow through mass of grain: Phase I ozonation slowly reaches the level of e.g. 50 ppm ozone after 3-6 days. Ozone reacts with materials of organic origin and thus disappears.

Ozone flow through mass of grain: Phase I ozonation slowly reaches the level of e.g. 50 ppm ozone after 3-6 days. Ozone reacts with materials of organic origin and thus disappears. Phase II ozonation quickly reaches the required level, because all reactive sites have been eliminated. You can renew it within a few hours even after 30 days since last ozonation.

Summary of research on ozone

Phase I ozonation reached 50 ppm ozone after 3-6 days (compared to phosphine fumigation)Phase II can be renewed within a few hours even after 30 days from the last ozonation.

Insect mortality: 90 - 100%. Ozone treatment without affecting grain quality parameters.

The musty grain smell was removed The device connects to the aeration silo opening and then provides: constant ozone flow through the mass of grain, obtaining the desired concentration of ozone toxic to insects, fungi, bacteria, ends the process. Ozonation completed

Ozone generating devices

The device connects to the aeration silo opening and then provides:● constant ozone flow through the grain mass,

● obtaining the desired concentration of ozone toxic to insects, fungi, bacteria,

● ends the process.

Technological advantages of ozonation:

● Ozonation is more effective than traditional fumigation.● Ozonation eliminates the activity of harmful organisms in 100%.

● Ozone does not cause resistance to pests such as phosphine.

● Ozone is safer than the gases used, such as PH3

● Ozonation treatments cheaper than fumigation.

● Ozone is much less harmful to grains than other gases.

● Ozone can replace PH3 and other gases.

● No toxic gas transport is required because ozone is produced on site